Brief introduction of PVC-DWV foam core pipes-2

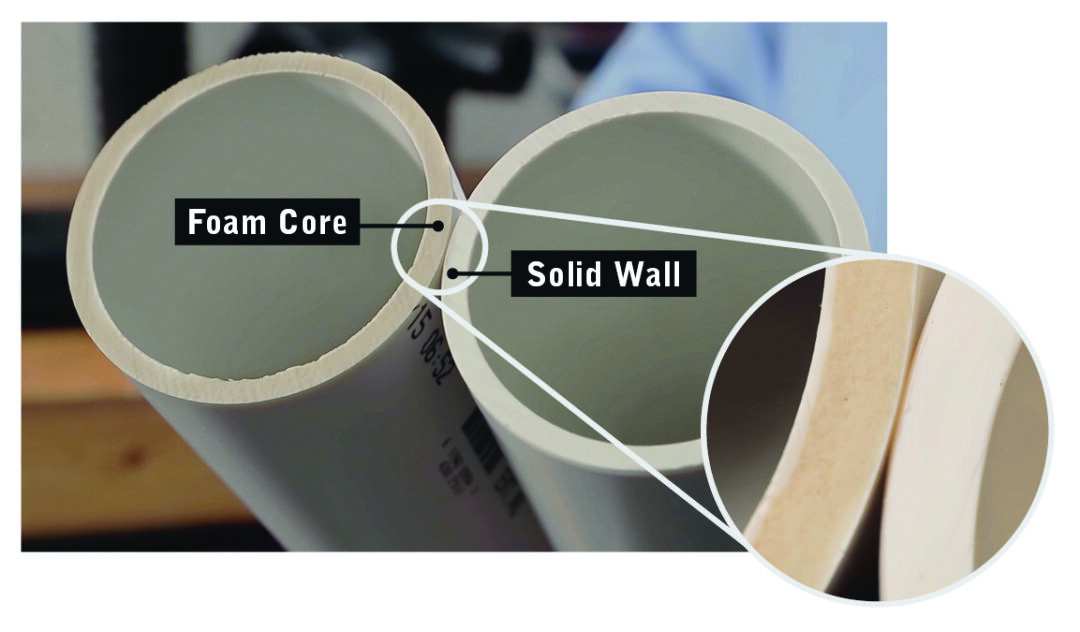

According to the China national standard GB/T 16800-1997 "Unplasticized polyvinyl chloride (PVC-U) pipes with a cellular core for drainage", the inner and outer solid wall layers must have good mechanical properties, such as tensile strength of not less than 43MPa, and good processing performance. Generally, SG-4 and SG-5 PVC resins are selected.

When producing PVC-U core foamed pipes, the extrusion of the core layer requires slightly higher fluidity than the solid wall layer, and SG-6 and SG-7 PVC resins should be selected. The core layer of the pipe must be tightly welded to the inner and outer skin layers.

The thickness ratio of the skin layer (inner and outer solid core layer) and the core layer is an important parameter in the production of foamed pipes. If the skin layer accounts for a large proportion, the density of the pipe is high, the pipe wall is heavy, and the advantage of less material used in the foamed pipe cannot be brought into play; if the skin layer accounts for a small proportion, the pipe is lighter, but the mechanical strength is somewhat reduced.

According to many years of production experience, it is believed that when the extrusion ratio of the skin layer to the core layer is 11:13, the quality of the pipe not only meets the national standards but is also relatively light (the overall density of the pipe is 0.95g/cm3).

2. Main performance characteristics of PVC foam core pipes:

(1) The impact strength is significantly improved, and its hoop rigidity is 8 times that of ordinary rigid PVC.

(2) It has a wide operating temperature range and can be used at -30 to 100 degrees centigrade, and its dimensional stability is good when the temperature changes.

(3) Its special core layer foaming structure improves the sound insulation performance of the pipe. The foaming core layer can effectively block the propagation of noise, greatly reducing the water flow noise. Compared with the solid wall drainage pipe, it can reduce the drainage noise by about 10dB.

(4) Good thermal insulation, the heat transfer efficiency is 35% lower than that of the solid wall pipe without foaming. The using temperature range is wide, and there is no condensation on the surface. When used for the insulation and transportation of hot and cold fluids, it can save insulation costs.

(5) Good mechanical properties. The use of the foaming core layer greatly improves the compressive strength of the inner wall. The cross-sectional mechanical characteristics of this pipe are more reasonable, so it has the advantages of high mechanical properties, good toughness, and strong bending resistance, which reduces the problem of breakage during construction and use.

To be continued...