Brief introduction of PVC-DWV foam core pipes-1

PVC-DWV foam core pipes, in some places, are also called as PVC-U pipes with a cellular core for drainage.

1. Introduction

As a best-selling construction material in Europe, U.S. and other industrialized countries, PVC-DWV foam core pipes are widely used in aqueducts, drainage systems in buildings as well as other pressure-free applications.

This lightweight (at a specific gravity of 0.95~1.0) and low-cost product requires installation that is as easy and rapid as any other PVC pipe. Its pressure resistance meets all physical requirements. The most highlighted feature of the PVC foam core pipe is its minimum noise when used in drainage systems.

PVC-DWV foam core pipe is a kind of PVC three-layer co-extruded core foam pipe, which is a new type of building pipe, especially suitable for building drainage.

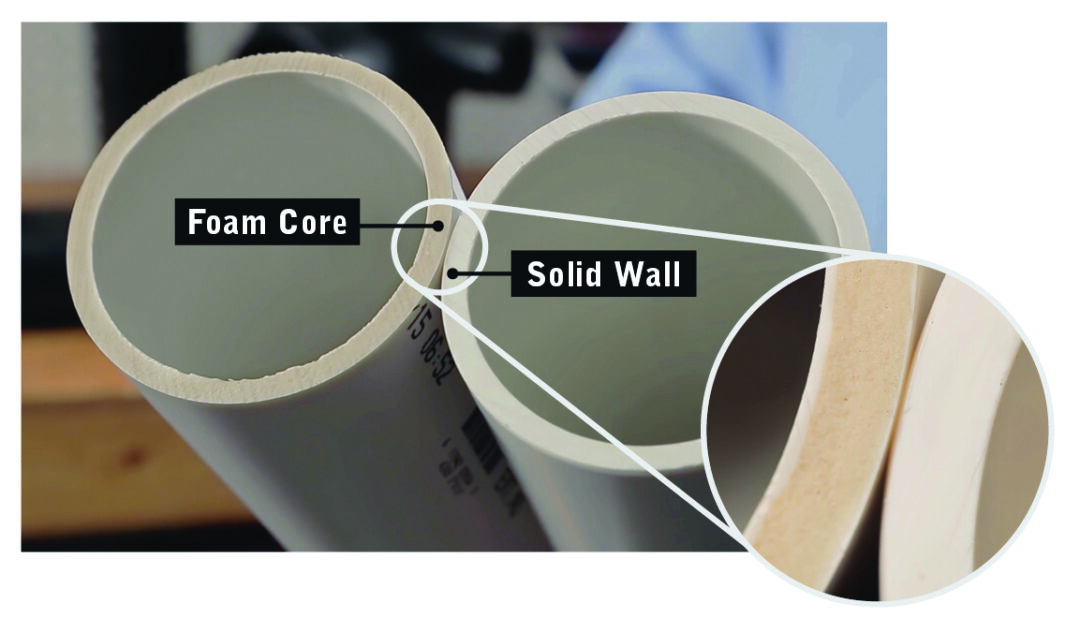

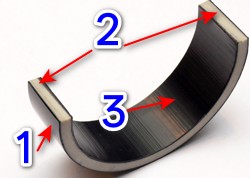

The core foam rigid polyvinyl chloride (PVC-U) pipe for drainage consists of three layers, as shown in the figure below. The components of the inner and outer layers are the same, which is the material of ordinary rigid PVC-U solid wall pipe. Only the middle foam layer is formed by foaming PVC resin.

1-Outer PVC hard layer;

2-PVC core foam layer;

3-Inner PVC hard layer

History of PVC foam core pipe/cellular core pipe

For Schedule 40 PVC cellular core pipe, commonly referred to as PVC foam core pipe, the American standard is ASTM F891, Standard Specification for Coextruded Poly(Vinyl Chloride) (PVC) Plastic Pipe with a Cellular Core.

This specification covers coextruded PVC plastic pipe with a cellular core and concentric inner and outer solid layers and is produced using a multilayer coextrusion die.

Product manufactured to this standard consists of a foamed PVC core and two thin skins of solid PVC. The term “foamed core” refers to the fact that in the extrusion process, a blowing agent is added to the PVC in the center layer. This blowing agent displaces a significant amount of PVC resin.

In essence, cellular core pipe has less PVC than solid wall PVC pipe. Cellular core PVC pipe is listed for gravity systems only and not rated for pressure. The print line on the pipe generally includes terms such as “COEX,” “CELLULAR CORE” and “NOT FOR PRESSURE.”

Cellular core pipe technology was developed in France in 1979 by Alphacan, a large, multinational pipe company. Alphacan introduced cellular core pipe into the French market in 1982, and the product quickly gained acceptance and market share.

The manufacturing process resulted in a pipe that was less expensive, lighter in weight and easier to cut. By the late-1980s, cellular core PVC pipe was produced regionally in parts of the United States by various pipe manufacturers, and it attained significant market share in single-family residential construction.

It is interesting to note that many plumbing professionals commonly refer to solid wall PVC pipe as “Schedule 40” and cellular core pipe as “foam core,” conflating the topics.

For an engineer reviewing submittals, it is important to remember that both solid wall and foam core are manufactured to Schedule 40 dimensions.

Schedule 40 refers only to the dimensions of the pipe (outer diameter, wall thickness, etc.) and has nothing to do with the material composition of the pipe. If an engineer scans the piping submittals and sees “Sch 40,” he may think he is getting solid wall PVC pipe. Submittals for solid wall PVC pipe will contain references to ASTM D2665 and ASTM D1785.

To be continued....