What needs to be paid attention to during the operation and debugging of the extruder-1

The twin-screw extruder has the advantages of high conveying efficiency, strong dispersion and mixing ability, good self-cleaning performance, short residence time of materials in the machine, uniform distribution and good adaptability, etc., and is widely used in the blending and modification between different plastics, between plastics and rubber, various additives and plastic blending, glass fiber, carbon fiber reinforced plastics, etc., and is the first choice for polymer modification continuous mixing equipment.

As the main equipment of factory production, the extruder is the first to bear the brunt of the difficulty and danger of operation, and a series of problems need to be paid attention to in the operation and debugging.

1. Before starting each extruder, check whether there are foreign objects in the barrel, up and down the hopper and inside, check whether the fastening bolts of each part are loose, whether the safety cover is firm, and whether the position of each button switch is correct, and then add enough lubricating oil to each lubrication part to do a good job in the cleaning and sanitation of the equipment.

2. Before starting the machine, check whether the temperature control is sensitive, whether the instrument is out of order, whether the cooling channel is unblocked, etc. Usually the thermometer, cooling water and other methods are used for detection.

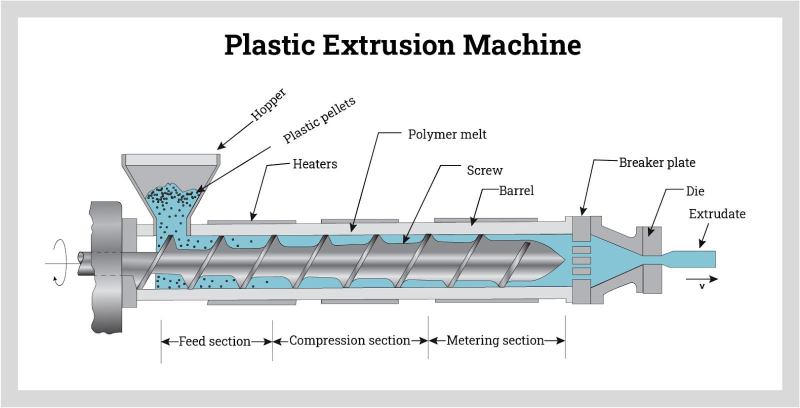

3. According to the extruder operation procedures, the screw, barrel and die head of the extruder are heated, and after the temperature rises to the set temperature, it must be kept warm for about 10 minutes before the machine can be started, so that the temperature of each part of the machine tends to be stable.

4. When you are ready to drive, notify the staff around the equipment. Be sure to tighten the connecting screws and bolts of each part of the die head while it is hot before starting. Before the material is extruded, the operator must not stand directly in front of the die to prevent injury accidents caused by bolt or screw breakage.

5. Start the motor for the rotation of the driving screw at low speed, check whether the pointer of the main motor working ammeter swings normally, if there is abnormal sound in the operation of the equipment or the screw is not running smoothly, it should be stopped immediately and repaired by relevant personnel.

(TO BE CONTINUED....)