Classification, Mechanisms, and Applications of ACR Processing Aids

In PVC processing, ACR (acrylic processing aids) are multifunctional additives that improve melt rheology, promote fusion/plasticization, and enhance melt strength.

This article summarizes their classification, mechanisms of action, applications, and representative case studies.

1. Types of ACR Processing Aids

General-purpose - Main component: methyl methacrylate (MMA) copolymers. Key features: promote fusion and increase melt strength; suitable for rigid PVC profiles, pipes, and other routine processing.

Foaming grade - Main component: acrylate copolymers bearing foam-promoting groups. Key features: increase melt elasticity and produce uniform cells; used in PVC foam products (e.g., foam board, wood-like materials).

High-flow grade - Main component: low-molecular-weight acrylate copolymers. Key features: markedly increase melt flow; ideal for thin-wall products and complex mold filling (e.g., injection parts, intricate profiles).

Impact-modified - Main component: core-shell acrylate copolymers. Key features: combine processing-aid and impact-modifier functions; for high-impact PVC (e.g., automotive parts, electronic housings).

Transparent grade - Main component: high-clarity acrylate copolymers. Key features: preserve transparency; used in clear PVC sheets, films, bottles, etc.

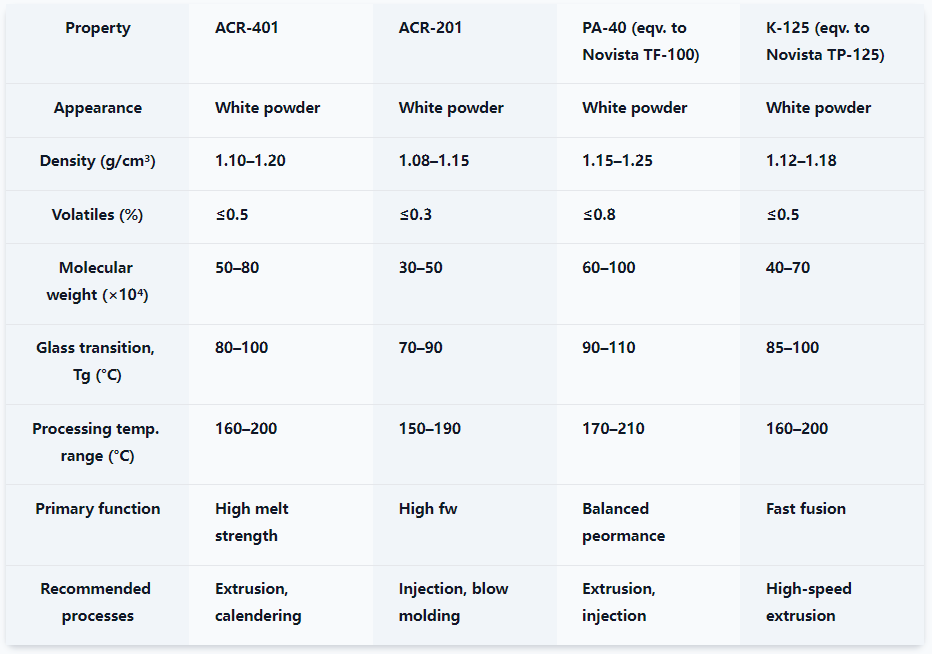

2. Typical General-Purpose ACR Grades and Physical Properties

3. Mechanisms of Action

1) Promote fusion - Polar functional groups on ACR interact with PVC chains, lowering inter-particle friction, accelerating fusion and shortening overall processing time.

2) Increase melt strength - Long ACR chains form a physical entanglement/mesh in the melt, increasing elasticity and preventing melt fracture (e.g., "sharkskin" during extrusion).

3) Improve flow - By reducing melt viscosity, ACR helps PVC fill the mold more easily, especially at high shear rates.

4) Stabilize the melt - ACR dampens melt-temperature fluctuations and suppresses localized overheating that could otherwise trigger PVC degradation.

5) Improve surface quality - Reduces fish eyes, flow marks and other surface defects, resulting in a glossier finish.

4. Significance of Key Physical Parameters

Density: Affects dispersion in PVC; density closer to PVC (approx. 1.4 g/cm3) tends to improve compatibility.

Volatiles: Lower volatiles reduce bubbles and surface defects (e.g., pinholes) during processing.

Molecular weight:

Higher (greater than or equal to 0.5 million): boosts melt strength and elasticity; suitable for profiles and pipes.

Lower (0.3-0.5 million): increases flow; suitable for injection molding and thin-wall parts.

Glass transition temperature (Tg): Higher Tg improves high-temperature melt stability, though flow may decrease.

Processing temperature window: Should align with typical PVC processing temperatures (approx.170-200 C) to avoid under-fusion or decomposition.

5. Selection Guidelines

By processing need and product type:

High melt strength required (e.g., profiles, pipes)

Recommended: ACR-401, PA-40 (eqv. to Novista TF-100).

Benefit: Higher molecular weight improves melt elasticity and prevents melt fracture during extrusion.

High flow required (e.g., injection parts, thin-wall items)

Recommended: ACR-201, K-125 (eqv. to Novista TP-125).

Benefit: Lower molecular weight reduces melt viscosity and speeds mold filling.

Balanced performance (general purpose)

Recommended: PA-40 (eqv. to Novista TF-100), K-125 (eqv. to Novista TP-125).

Benefit: Good balance of fusion speed and melt strength across multiple processes.

Practical tips:

Match to process: Extrusion - general-purpose or foaming ACR; Injection molding - high-flow or impact-modified ACR.

Dosage: typically 0.5-5 phr; excessive dosage may over-lubricate the melt and add cost without benefit.

Synergy: combine with Ca-Zn stabilizers, epoxidized soybean oil (ESBO), etc., to further optimize processing and heat stability.

6. Application Areas and Representative Cases

1) General-purpose ACR

Applications: Rigid PVC profiles, pipes, sheets.

Case studies:

- Window/door profiles - Adding 1-2 phr of a general-purpose ACR (e.g., ACR-401) significantly increases extrusion speed, reduces surface defects, and improves dimensional stability.

- PVC pipes - In double-wall corrugated pipe formulations, ACR raises melt strength and prevents collapse during corrugation.

2) Foaming-grade ACR

Applications: PVC foam board, wood-like products, footwear.

Case studies:

- PVC foam board - Adding 3-5 phr foaming ACR (e.g., ACR-530, eqv. to Novista TF-530) yields fine, uniform cells and approx. 20% density reduction while maintaining high strength.

- Wood-like flooring - ACR tunes the foam structure to achieve wood-grain appearance, while improving weatherability and compressive strength.

3) High-flow ACR

Applications: Thin-wall injection parts and complex molds.

Case studies:

- PVC injection fittings - With approx. 1.5 phr high-flow ACR, filling time is reduced by approx. 30%, eliminating short-shots and weld lines.

- Medical tubing - Improves flow in thin sections to ensure uniform wall thickness, meeting medical precision requirements.

4) Impact-modified ACR

Applications: High-impact PVC products and automotive parts.

Case studies:

- Automotive instrument panels - Adding 8-10 phr core-shell ACR raises impact strength by approx. 50% while maintaining gloss.

- Electronics housings - In flame-retardant PVC, ACR synergistically improves impact strength and helps achieve UL94 V-0.

5) Transparent ACR

Applications: Transparent PVC sheets, films, and bottles.

Case studies:

- PVC shrink film - With approx. 1 phr transparent ACR, melt uniformity improves and film transmittance exceeds 90%.

- Mineral-water caps - ACR reduces haze during injection, improving sealing and appearance.

7. Detailed Representative Cases

A) Profile extrusion (window/door frames)

- Grade: ACR-401

- Dosage: 1.5-2 phr

- Effects: approx. 30% higher melt strength; reduced extrusion deformation and surface waviness. Fusion time shortened by approx. 15%, improving throughput.

- Typical parameters: Mw approx. 0.6 million; Tg approx. 90 C; suitable processing temperature 170-190 C.

B) PVC injection fittings

- Grade: ACR-201

- Dosage: 1-1.5 phr

- Effects: approx. 20% higher melt flow; approx. 25% shorter filling time; defects such as short-shots and weld lines eliminated.

- Typical parameters: Mw approx. 0.4 million; Tg approx. 80 C; suitable injection temperature 160-180 C.

C) High-speed pipe extrusion

- Grade: K-125/ NOVISTA TP-125

- Dosage: 1-2 phr

- Effects: Extrusion speed increased by approx. 20%; surface roughness Ra less than or equal to 0.8 um; improved heat stability with reduced yellowing risk.

- Typical parameters: Mw approx. 0.5 million; Tg approx. 95 C; suitable for 180-200 C high-speed extrusion.

8. Notes on Use

1) Dosage control - Typically 0.5-3 phr; excessive amounts can over-lubricate the melt or waste cost.

2) Work with lubricants - Calcium/zinc stearates provide external lubrication, while ACR mainly acts as internal lubrication; balance the formulation.

3) Temperature sensitivity - For high processing temperatures (greater than 200 C), pair with heat stabilizers (e.g., organotin or Ca-Zn) to prevent degradation.

9. Summary

By tuning molecular weight and functional groups, general-purpose ACR grades can be precisely matched to different PVC product requirements:

- High-melt-strength grades (e.g., ACR-401) for profiles and pipes.

- High-flow grades (e.g., ACR-201) for injection molding and complex mold filling.

Thoughtful molecular design makes ACR a key enabler of efficient PVC processing and high product quality. Selecting the right ACR type and optimizing the formulation can significantly increase productivity, reduce energy consumption, and expand PVC into higher-end applications (e.g., medical, automotive, construction).